Accurate anemometer calibration can only be performed in a wind tunnel. However, the installation of such a facility involves tremendous investment, and its setup and maintenance are not easy tasks. This section describes some simple methods of checking anemometer operation to achieve the minimum required level of performance.

Comparison by Beaufort Scale

Comparing wind speeds measured with an anemometer to Beaufort Scale observation is the simplest method. However, as it provides only a rough estimation, its accuracy cannot be guaranteed.

Starting-threshold torque measurement

The torque of the starting threshold for a wind vane or anemometer is determined at the design and manufacture stages of each model. When a new instrument is introduced, its torque value should be checked with the manufacturer, or the torque at the starting threshold for the wind speed and the wind direction should be measured. The relevant data should be kept for reference, and subsequent instrument checks should be carried out with reference to these values. A tension gauge is used to measure the starting-threshold torque. Take several measurements and use the average as this torque value.

Another simple method of measuring starting-threshold torque is to use a weight equivalent to this torque value.

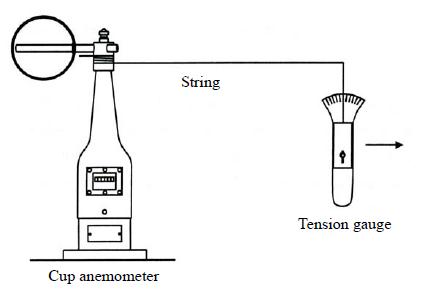

(1) Starting-threshold torque measurement using a tension-gauge

- a. Place a cup anemometer horizontally in a wind-free indoor environment and connect it to a tension gauge with a string of about 50 cm in length as shown in Figure 1.

- b. Slowly pull the tension gauge horizontally in the direction of the cup anemometer’s rotation. Record the reading on the meter when the cup starts rotating.

- c. After repeating Step b several times, average the measured values to obtain the starting-threshold torque.

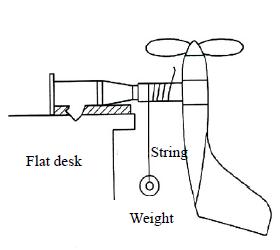

(2) Testing of wind-direction measurement initiation using a weight

- a. Prepare a piece of string measuring about 1 m in length and a weight of about 35 g.

- b. As shown in Figure 2, set the anemometer horizontally, wind the string several times around the supporting shaft and hang the weight at the end of the string. Check the wind-direction axis to ensure that rotation starts smoothly in all directions.

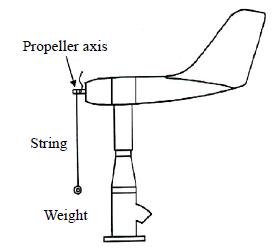

(3) Testing of wind-speed measurement initiation using a small weight

- a. Prepare a piece of string measuring about 1 m in length and a weight of about 7 g.

- b. As shown in Figure 3, set the anemometer vertically. Detach the propeller and wind the string around its shaft. Hang the weight at the end of the string and check that the shaft rotates smoothly.

Starting-threshold torque measurements and tests conducted using weights to check wind direction and wind-speed measurement initiation are solely for the purpose of verifying smooth start-up in anemometers. They are not intended to guarantee the accuracy of calibration performed at individual wind speeds.